|

| February 28, 2017 | Volume 13 Issue 08 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Next Big Thing:

Father-son team create liquid metal 3D-printing system [UPDATED]

Is this machine the next big thing in additive manufacturing?

By Grove Potter, University at Buffalo

A father and son team in the START-UP NY program in Buffalo, NY, have invented a liquid metal printing machine that could represent a significant transformation in manufacturing. A breakthrough idea five years ago by former University at Buffalo student Zack Vader, then 19, has become a machine that prints three-dimensional objects using liquid metal.

Zack (left) and Scott Vader inside their Getzville, NY, factory. [Credit: Douglas Levere].

Vader Systems is innovating and building the machines in a factory in the CrossPoint Business Park in Getzville, NY, near Amherst. Zack's father, Scott, a mechanical engineer, is the CEO. Zack is the chief technology officer. His mother, Pat Roche, is controller.

The machine is so novel it may represent a quantum leap in the ability to print three-dimensional objects in metal. Other metal printers exist, but most use a process of laying down powdered metal and melting it with a laser or electron beam. In that process, some particles of the powder do not get melted, creating weakened spots.

Manufacturers are very interested in the Vader machine, with one automotive parts maker expressing an interest in eventually buying at least 50 of them. A printer with multiple nozzles could cost more than $1 million.

[Designfax Editor's note: On March 10, 2017, Biz Journals [Buffalo Business First] reported that Lockheed Martin will be the first commercial company to purchase a Vader Systems machine, an exclusive deal that will give Lockheed Martin "the advantage of using innovative technology before their competitors."]

UB engineering faculty and students work closely with the company

University at Buffalo (UB) has been a source of intellectual assistance, grants, and personnel for the startup as it transforms from a brilliant idea into an industry.

Two products printed with Vader Systems machine. [Credit: Douglas Levere]

The Vaders were working on their invention in the basement of their home in Amherst when Scott decided to reach out to UB for help. "We were working alone in our basement and tackling some pretty deep technical problems," he said.

"We knocked at the door of the university, and they welcomed us in," Scott said. "They set up an impressive first meeting with faculty experts within UB, and they said, ‘What are you trying to do? What are your problems, and how can we help?'"

The Vaders now have three faculty advisors, are part of the START-UP NY tax-free entrepreneurial program, and have won grants from UB's Center for Industrial Effectiveness (UB TCIE), UB's Center for Advanced Biomedical and Bioengineering Technology (UB CAT), and a National Grid grant through UB.

In addition, and perhaps most importantly, Scott Vader said, access to university students for internships has helped the company grow. Vader Systems already has hired three mechanical engineering graduates.

"This is what makes really good young engineers, to go from the theory and being able to mix in an internship with a local industry," he said. "They realize that the lab they took is something a company really needs."

Inspiration spawned by disappointment

Zack Vader, now 24, started focusing on metal printing when his plans to hire a company to 3D print parts for a microturbine generator were stymied. No company could print the parts he needed, so he decided to make his own metal printer. His breakthrough came when he thought to expose molten metal in a confined chamber with an orifice to a pulsed magnetic field. The transient field induces a pressure with the metal that ejects a droplet. That was the key to making droplets of liquid metal eject from a nozzle.

VIDEO: Scott and Zack Vader of Vader Systems explain how their liquid metal 3D printer works. [Video credit: University at Buffalo]

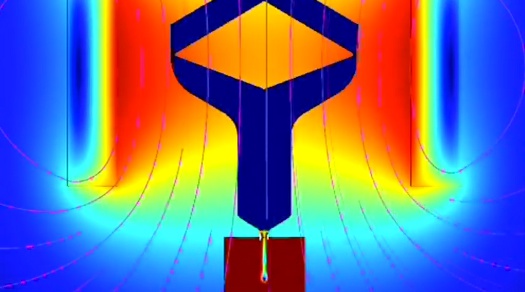

Professor Edward P. Furlani, PhD, in UB's Chemical and Biological Engineering and Electrical Engineering departments, said that Vader's process mimics drop-on-demand inkjet printing and is based on the principles of magnetohydrodynamics (i.e., the manipulation of conductive fluids using a magnetic field). In the Vader device, an electrically pulsed magnetic field permeates liquid metal in an ejection chamber and creates circulating electrical currents that interact with the magnetic field to produce a pressure that squeezes a droplet out of the ejector nozzle.

Because it combines magnetohydrodynamics (MHD) and liquid metal jet printing (LMJP), Vader calls its machine a "MagnetoJet."

The process uses a pulsed magnetic field to help "squeeze" a drop of liquid metal from a heated nozzle. [Image: University at Buffalo video screenshot]

"It's a transformative technology," Furlani said. "It's very exciting interdisciplinary engineering. I think its application base will continue to broaden and expand for the foreseeable future."

Ciprian N. Ionita, PhD, a research assistant professor in the Biomedical Engineering Department -- a joint effort of the School of Engineering and Applied Sciences and the Jacobs School of Medicine and Biomedical Sciences at UB -- foresees the Vader Systems printer ultimately printing out custom stents and other surgical devices right in the hospital.

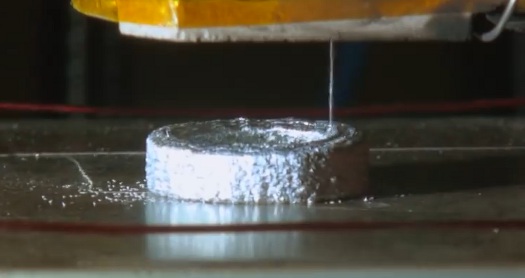

A part being created using the Vader liquid-metal printing process. [Image: University at Buffalo video screenshot]

"This is a game changer," he said. The metal powder used in the current metal printing processes is a contaminant that is difficult to clean up and can be toxic inside the body.

The Vader printer also will be valuable making custom knee and hip replacements, he said.

Cheaper, faster, better

The third UB professor advising the Vaders, Chi Zhou, an assistant professor in the Industrial Systems Engineering Department and a 3D-printing expert, said another advantage of the Vader system is that it is "much, much cheaper" than using powered metal.

The Vader Systems Mk1 machine.

"I can see at this stage that it can complement traditional metal printing, but later, maybe 10 years later, it can dominate the metal printing market because it can print better quality, cheaper, and faster," Zhou said.

Zhou has helped write original open-source software to control the printer. "If they want to add functionality, we can. We have the source code," he said.

One of the most fascinating qualities of a 3D printer is that a complex part is just as cheap to make as a simple part.

"Complexity does not add cost," Zack Vader said, which is the opposite of traditional manufacturing. That makes the machines very attractive to companies making many complex parts.

Steel printing on the horizon

On a Vader machine, a strand of aluminum is fed into a heat element that melts it at 750 degrees Celsius (1,382 degrees Fahrenheit). The liquefied metal is then passed to a ceramic tube that forms an ejection chamber and has a submillimeter orifice. A magnetic coil surrounds the tube and receives a short-lived electrical pulse to create a pressure within the tube that ejects a droplet of liquid metal through the orifice. The ejected drop is projected downward onto a heated platform that maneuvers to create solid 3D shapes based on layer-by-layer deposition and the coalescence of the droplets.

Zack Vader said plans are to modify the device, adding nozzles to make it faster (potentially, there could be thousands of printing heads within one machine). Eventually, the machines will be able to melt and print steel at 1,400 C (2,552 F).

As the machine evolves, the Vaders plan to expand their operation into an assembly line manufacturing facility. Applications for the device run the gamut. Scott Vader said the automotive industry may be interested in making parts that are now solid metal into hollow and honey-combed structures. The hollow parts would be lighter, stronger, and much cheaper.

And as for the tiny generator that Zack Vader was hoping to print, it may emerge again someday, now that the technology to make it is advancing.

"That's just been put on the shelf for a while," he said.

Some Vader Systems Mk1 liquid metal printing machine stats

Material: Aluminum 4043, 6061, 7075

Input material form: 0.035 in. (0.9 mm) wire

Material packaging: 16-lb spools

Droplet range: 300 to 500 micron

Droplet rate: 1,000 droplets per second

Build envelope (x,y,z): 12 in. x 12 in. x 12 in. (300 mm x 300 mm x 300 mm)

Max. part mass: 80 lb (40 kg)

Deposition rate: 1 lb per hour based on 500-micron droplet size

Shield gas: Argon

Motion controller: Siemens Flagship 840D-SL with 19-in. touchscreen

Max feed rate: 39.4 in./sec (1,000 mm/sec)

Machine weight: 2,500 lb

Floor space: 41.57 in. x 113.52 in. (includes 12 in. additional for Argon tank)

Software: Converts standard STL object files from CAD software to Siemens standard G-Code

Speed vs. powder bed infusion: 2x faster

Part cost vs. powder bed fusion: 90% reduction

*The Mk2 machine, projected for release late 2018, will contain 10 print heads and produce parts 30x faster than the Mk1, according to Vader Systems.

UPDATED: Want to know a few more specifics? We do, too!

Designfax asked Vader Systems for some more details on the system capabilities and the final products. Jennifer Moran, Director of Sales & Marketing, Vader Systems, provided the responses.

How do you control the accuracy of the material lay down? What is the tolerance/dimensional accuracy?

Moran: The tolerance/accuracy is largely controlled by the orifice size of the nozzle. We have experimented down to 50 micron but are printing mostly in the 300-500 micron droplet range for the Mk1. As the technology matures, we do expect to achieve finer details and smaller droplet sizes over time. The placement of the droplets themselves is highly accurate.

Does a part need further finishing? The images from UB and the video show a piece that looks pretty rough. In the automaker-use example, will parts need additional milling/surface work?

Moran: Virtually all 3D printing processes require some form of post-processing to achieve desired finish. The parts produced via this process have a finish similar to what you'd see with a sand cast part.

Can this technology compete with laser sintering when it comes to building in voids/cavities? This is a strength of most plastic and metal 3D printers.

Moran: One advantage of this technology is that you could create voids within a part. This is not possible with powder processes because the loose powder becomes trapped with no way to remove it.

Can you please give an example part cost comparison to laser sintering? Maybe from the automotive example?

Moran: Our initial findings show a 90% reduction in costs when compared to powder bed fusion technologies.

Initially, what parts first piqued the interest of early adopters? Have you begun finished-part testing for strength, durability, and longevity?

Moran: We are still in the early days of this technology. We have sold our first system to RIT (Rochester Institute of Technology), which is being installed the end of this month. We have had strong interest from other R&D divisions of large manufacturers as well as aerospace/military/defense. But we are not able to provide specific use applications at this time. Similarly, we have not yet undergone full material/strength testing, but early results are positive. Dr. Denis Cormier from RIT has provided us with early micrographs which show the very high density and even grain structure, which has thus far been exciting to those "in the know" in 3D-printing circles. We expect more tests to come and results published as we continue to develop our university partners.

Published February 2017

Rate this article

View our terms of use and privacy policy